INDOSTAR Fe 550D TMT Bar

Strength You Can Trust

Built on uncompromising quality, earned through decades of trust, and proven by superior strength, IndoStar Steel stands for reliability in every structure it supports.

As part of Galwalia Ispat Udyog Pvt. Ltd. (SPNG Group), IndoStar operates a fully automated, integrated manufacturing facility, delivering premium TMT bars, structural steel, billets, and ready-made stirrups.

Every stage of manufacturing is precision-controlled to meet stringent national and international standards, ensuring consistent performance, long-term durability, and a sustainable future for the communities we build.

Read more About Us

Fire Resistance

Easy Bendability

High Strength

Excellent Bonding

Super Seismic Resistance

Corrosion Resistance

Earthquake Resistance

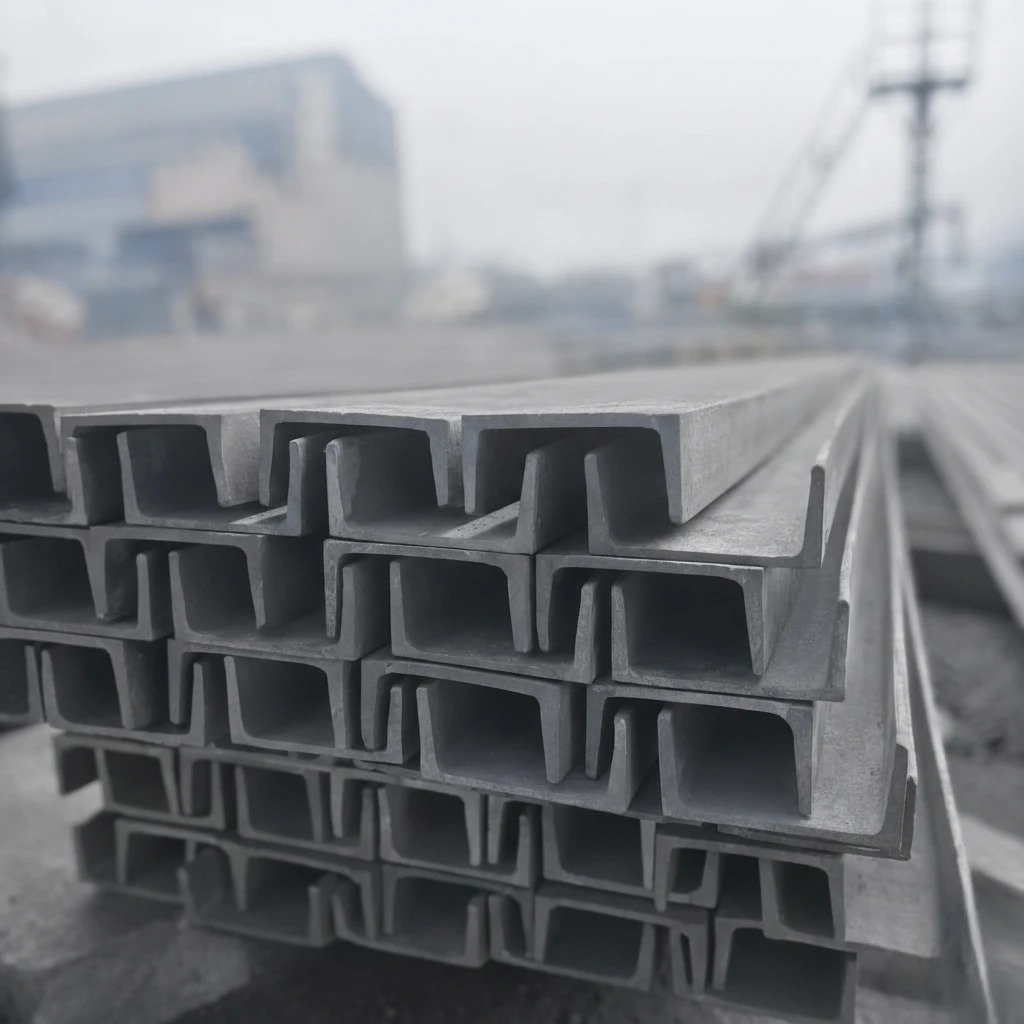

Indostar delivers a focused, high-quality range of steel products for innovative construction. Our flagship TMT bars are engineered for consistent strength and ductility, giving your structures long life and safety. To maintain consistant quality in all our products we use in house manufactured billets that form the backbone of our bars' reliability.

For faster, cleaner sites, we offer ready-to-use stirrups and cut & bend solutions that reduce waste and speed up execution. Backed by rigorous testing and process discipline, Indostar's product line is built to serve homeowners, contractors, and infrastructure projects with the same promise Steel Sahi, Toh Sab Sahi.

Strength You Can Trust

The Backbone of Construction

Purity That Shapes Strength

Complete manufacturing is done in-house without outsourcing.

Rigorous testing of raw materials and production processes.

Seamless melting, casting, rolling, cooling, and packing.

Advanced automation ensures consistency and precision.

Enhanced strength and durability using German technology.

Accurate weight and dimensions as per ISI standards.

At Indostar, we believe we borrow the earth from future generations. Sustainability is built into our manufacturing through eco-friendly technologies, waste-to-wealth recycling, water reuse, and renewable solar energy. By conserving resources, reducing emissions, and minimizing waste, we ensure responsible steel production that supports economic growth while protecting the environment for tomorrow.

Indostar operates a fully integrated, in-house manufacturing process starting with continuous billet casting and progressing through automated rolling, German QST quenching, controlled cooling, and precision cutting. This seamless, automated system ensures uniform strength, superior ductility, accurate weight, and consistent dimensions in line with BIS standards. Every Fe 550D TMT bar is verified at Indostar Lab, our NABL-accredited in-house testing facility (ISO/IEC 17025:2017), ensuring complete quality assurance from billet to finished bar.

Learn How TMT Bars Are Made

At Indostar, strength is proven, not assumed. Every Fe 550D TMT bar is rigorously tested at our NABL-accredited in-house laboratory to ensure compliance with BIS standards for chemical composition, mechanical performance, and dimensional accuracy. This disciplined approach ensures steel that delivers consistent strength, safety, and reliability on every site.

Indostar (SPNG) offers TMT rebars, in-house billets, and precision stirrups/cut-&-bend a focused lineup engineered for strength, consistency, and faster site execution. Our German QST technology, hot-billet charging, and automated rolling systems ensure precision, energy efficiency, and consistency across every bar.

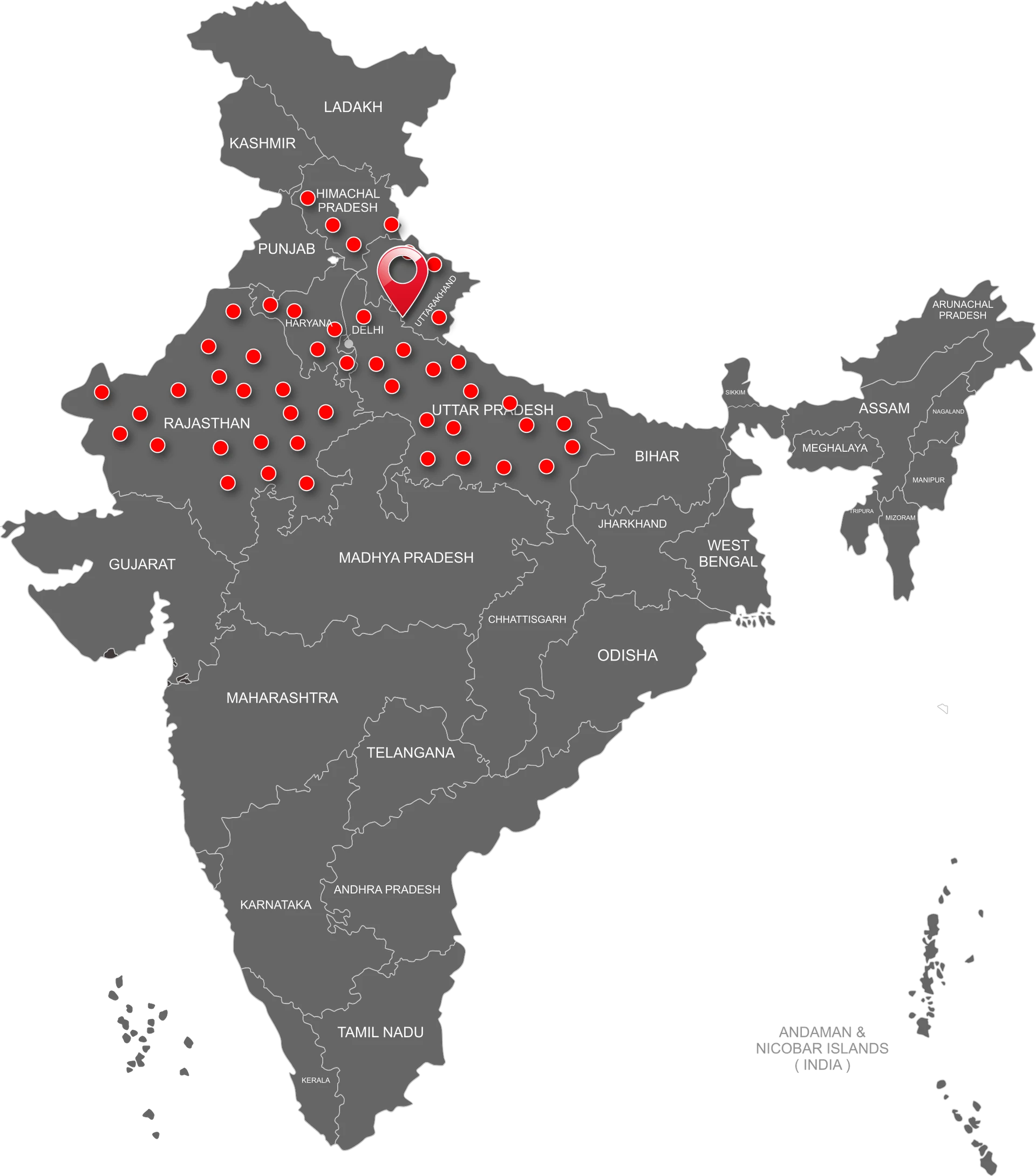

Indostar Steel has established a strong and growing presence across key construction markets, supported by a trusted dealer network. Our partners rely on us for consistent supply, dependable quality, and responsive support, ensuring Indostar Fe 550D TMT Rebars reach projects on time and perform reliably on every site.

Homeowners, Builders, engineers, contractors and dealers across markets trust Indostar for its consistent quality, reliable performance, and transparent manufacturing. From on-time deliveries to steel that performs exactly as promised, Indostar Fe 550D TMT Rebars have earned confidence in projects where strength, safety, and long-term durability matter most.

As an architect, material reliability is non-negotiable for me. SPNG Indostar consistently delivers steel that meets structural requirements without compromising design intent. Their quality standards and uniform strength give complete confidence during execution. It’s a brand I trust for long-term performance.

Ar. Akshat Garg

Architect

SPNG Indostar has proven to be a dependable partner for modern construction needs. The consistency in their TMT bars ensures structural safety while allowing flexibility in design. Their commitment to quality makes project planning smoother and execution more efficient.

Ashish Mohan

Architect

What stands out about SPNG Indostar is their focus on strength and reliability. Their steel integrates seamlessly into complex structural designs, giving assurance from foundation to finish. It’s a material choice that supports both creativity and safety.

Jasdeep Sethi

Architect

In today’s construction environment, using trusted materials is crucial. SPNG Indostar offers consistent quality that architects can rely on for both residential and commercial projects. Their products bring confidence at every stage of construction.

Kaushal Solanki

Architect

A single place for our blogs, news, press releases, awards, certifications and multimedia.

What Are TMT Bars? TMT Bars (Thermo‑Mechanically Treated bars) are high‑strength reinforcement steel bars with a tough outer surface and a softer, ductile core, engineered specifically for RCC structures. This unique combination of strength and flexibility helps structures resist heavy loads, earthquakes, and thermal stresses while ensuring long‑term durability. For SPNG Indostar, TMT bars areContinue reading "Learn How TMT Bars Are Made?"

India sits on one of the world’s most seismically active regions, with 59% of its landmass vulnerable to earthquakes. From the Himalayan foothills to the eastern seismic gap, the threat is real and ever-present. TMT Steel Bars have emerged as the cornerstone of earthquake-resistant construction, providing the ductility, strength, and reliability needed to protect lives and property.Continue reading "Earthquake-Safe Homes in India: Why TMT Steel Bars Are Critical for Structural Safety"

India’s steel industry, traditionally one of the most energy-intensive sectors, is undergoing a green revolution. Sustainable Steel Manufacturing in India is no longer optional, it’s essential for meeting national carbon reduction targets and global green building standards. The Imperative for Sustainable TMT Production Steel production accounts for 7-9% of global CO2 emissions, but TMT manufacturing canContinue reading "Sustainable Steel Manufacturing in India: How Modern TMT Production Supports Green Construction Goals"