When it comes to heavy engineering projects, the structural components used must combine strength, reliability, and cost-effectiveness. Among the most sought-after materials in the industry are Mild Steel Angles—structural elements that have become indispensable for engineers and contractors working on bridges, industrial frameworks, power infrastructure, and complex machinery. But what makes MS Angles the preferred choice for demanding applications?

Understanding the advantages and applications of these critical components reveals why they remain a cornerstone of heavy engineering construction.

What Are Mild Steel Angles?

Mild steel angles, commonly referred to as MS Angles, are L-shaped structural sections made from low-carbon mild steel. These angles feature two perpendicular flanges meeting at a 90-degree angle, creating a robust geometric structure that provides exceptional load-bearing capacity.

Superior Material Properties

Excellent Weldability and Machinability

One of the primary reasons MS Angles are favored in heavy engineering projects is their superior weldability. Made from low-carbon mild steel, these angles can be easily welded using standard welding techniques, allowing engineers to create complex connections and frameworks without compromising structural integrity.

Additionally, MS angles offer outstanding machinability, enabling fabricators to cut, shape, and modify them according to project specifications without difficulty. This flexibility is invaluable when working on custom engineering solutions.

Optimal Strength-to-Weight Ratio

Mild Steel Angles provide moderate tensile strength while remaining lightweight compared to other structural materials. This balance is crucial in heavy engineering where materials must bear substantial loads without adding excessive weight to the overall structure. The resulting strength-to-weight ratio ensures efficient material usage and cost savings.

Flexibility Under Stress

Unlike brittle materials, mild steel angles offer the flexibility to absorb stress and strain without breaking. This ductility is especially important in applications where structures experience dynamic loads, vibrations, or occasional impacts. For engineers designing heavy machinery or transportation infrastructure, this property provides an added safety margin.

Why Heavy Engineering Projects Prefer MS Angles?

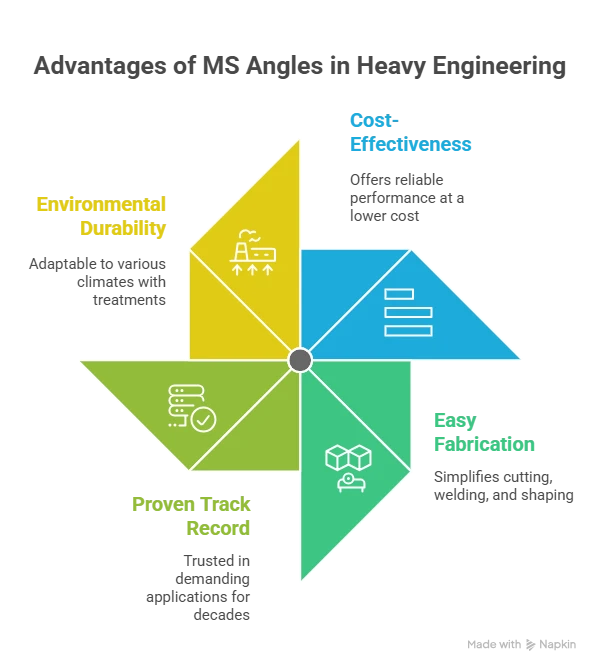

1. Cost-Effectiveness Without Compromise

Budget constraints are real in heavy engineering projects. MS Angles deliver exceptional value—offering reliable structural performance at a fraction of the cost of premium alloy steels. This cost advantage allows project managers to allocate resources more efficiently without sacrificing quality or safety.

2. Easy Fabrication and Installation

Time is money in construction and engineering projects. MS angles’ ease of cutting, welding, and shaping accelerates fabrication timelines. Their lightweight nature compared to other materials simplifies handling, transportation, and installation on-site, reducing labor costs and project duration.

3. Proven Track Record in Demanding Applications

MS Angles have been trusted for decades in applications that demand uncompromising reliability:

- Building Frames and Structures: Supporting multi-story buildings, factories, and warehouses

- Bridge Construction: Providing critical structural support for spans that carry heavy traffic loads

- Machine Frames: Forming the backbone of industrial machinery and equipment

- Industrial Racks: Creating robust storage and support systems for heavy materials

- Transportation Structures: Used in chassis fabrication, rail tracks, and vehicle frameworks

- Power Infrastructure: Providing structural support to electrical grids and transmission towers

4. Environmental Durability with Treatment Options

While mild steel requires surface treatment for enhanced corrosion resistance, this is a significant advantage in heavy engineering. Engineers can choose from multiple protection methods—galvanization, painting, epoxy coating, or weathering steel, depending on the environmental conditions and project budget. This flexibility ensures that MS Angles can be adapted to coastal environments, industrial zones, or harsh climates.

Applications Across Heavy Engineering Sectors

Industrial Manufacturing

MS angles form the structural backbone of industrial facilities, supporting heavy machinery, conveyors, and production lines. Their ability to handle continuous loading and vibration makes them ideal for factories and manufacturing plants.

Infrastructure Development

From bridges spanning rivers to elevated highways supporting millions of vehicles, MS Angles provide the structural integrity that infrastructure demands. Their proven performance in large-scale projects has made them a standard specification for civil engineers.

Power and Utilities

Electrical transmission towers, substation frameworks, and utility structures rely on MS angles for structural support and stability. Their cost-effectiveness makes them particularly valuable in utility projects where kilometer-long structures must maintain consistent quality.

Transportation and Logistics

Rail tracks, transport vehicle chassis, and loading dock structures depend on MS angles for durability and load-bearing capacity. The flexibility of the material ensures reliable performance even under the stresses of constant use.

Heavy Machinery and Equipment

Industrial equipment manufacturers choose MS Angles for constructing machine frames, presses, and industrial equipment. The material’s weldability allows for precise engineering and complex assembly.

Why Choose Indostar as Your MS Angles Supplier?

As a best ms angles manufacturer in India, Indostar maintains strict quality standards, ensuring consistent dimensions, strength properties, and surface finishes. The company’s commitment to excellence means:

- Rigorous testing and quality control on every batch

- Compliance with national and international standards

- Reliable supply and nationwide distribution network

- Technical support for project-specific requirements

- Competitive pricing without compromising quality

Conclusion

Mild Steel Angles continue to dominate heavy engineering projects because they masterfully balance strength, workability, cost-effectiveness, and reliability. Whether you’re building a bridge, constructing an industrial facility, or developing transportation infrastructure, choosing the right MS angles supplier in India is crucial.

SPNG Indostar stands out as a trusted partner, delivering quality MS Angles that have proven their worth across countless demanding projects. When heavy engineering demands excellence, Indostar MS Angles deliver the structural foundation that projects depend on for success, safety, and longevity.

For your next heavy engineering project, partner with the top ms angles manufacturer in India and experience the difference that commitment to quality makes.