When it comes to construction, the quality of materials you choose directly impacts the safety, durability, and longevity of your structure. Among the most critical decisions builders and contractors face is selecting the right TMT Bars. Yet, many make costly mistakes during this process that compromise structural integrity and lead to expensive repairs or, worse, safety hazards. Understanding these common pitfalls and how to sidestep them is essential for anyone investing in construction.

Let’s explore the top mistakes people make when selecting TMT bars and how to make smarter choices.

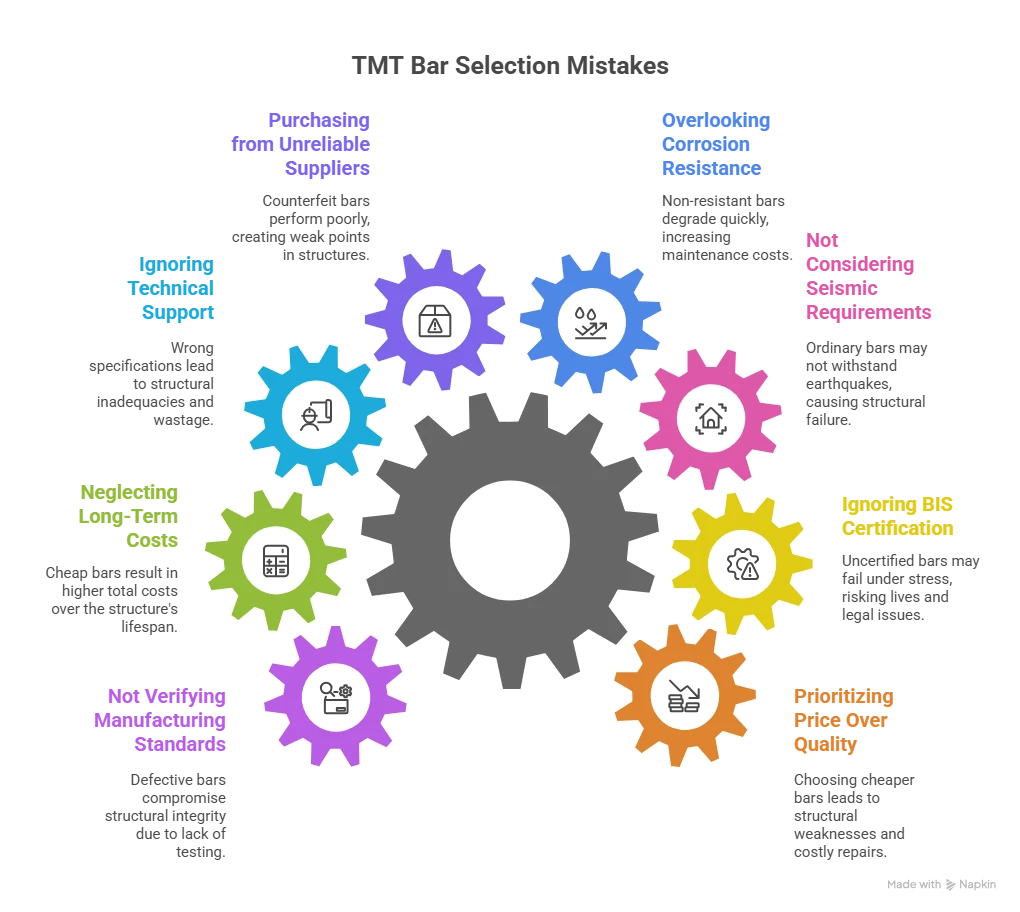

Mistake 1: Prioritizing Price Over Quality

The Problem: The most common error is choosing TMT bars based solely on price. While budget constraints are real, opting for cheaper, lower-quality bars to save money is a false economy.

The Consequence: Low-quality TMT bars often have inconsistent strength, poor corrosion resistance, and inferior bonding with concrete. This leads to structural weaknesses that manifest years later, resulting in costly repairs, reinforcement work, or even structural failures.

How to Avoid It: Invest in quality TMT bars from reputable manufacturers like Indostar TMT bars, which undergo rigorous testing and adhere to BIS standards. The slightly higher upfront cost is offset by decades of durability, reduced maintenance, and peace of mind. Quality is an investment, not an expense.

Mistake 2: Ignoring BIS Certification and Standards

The Problem: Not all TMT bars are created equal. Some manufacturers cut corners by skipping certifications or not adhering to Bureau of Indian Standards (BIS) norms.

The Consequence: Uncertified or substandard bars may fail under stress, especially in earthquake-prone zones or high-load structures. This puts lives at risk and can result in legal liability.

How to Avoid It: Always verify that your TMT Bars Supplier in India provides BIS-certified products with proper documentation. Indostar TMT bars are manufactured strictly according to BIS IS 1786 standards, ensuring compliance with all quality parameters. Ask for certificates of conformance before making your purchase.

Mistake 3: Not Considering Seismic Requirements

The Problem: Many builders select TMT bars without considering whether the product is suited for the seismic zone of their location.

The Consequence: In earthquake-prone regions, ordinary TMT bars may not possess the required ductility and flexibility to absorb seismic shocks, leading to structural failure during tremors.

How to Avoid It: Partner with a best TMT bar manufacturer in India that offers grades specifically designed for seismic resilience. Indostar offers multiple grades, including INDOSTAR HD Fe 550 and PRATULYA Fe 600, engineered with superior ductility for earthquake resistance. Consult with structural engineers to select the appropriate grade for your location.

Mistake 4: Overlooking Corrosion Resistance

The Problem: In coastal areas, industrial zones, or areas with high pollution, corrosion is a serious concern. Many builders fail to account for this when selecting TMT bars.

The Consequence: Non-corrosion-resistant bars rust and degrade quickly, reducing the structural lifespan and increasing maintenance costs significantly. Corrosion can compromise the entire structural integrity.

How to Avoid It: Choose TMT bars with superior corrosion-resistant properties. Indostar TMT bars are manufactured using advanced processes that impart exceptional corrosion resistance, making them ideal for challenging environments. Discuss environmental factors with your supplier to ensure proper product selection.

Mistake 5: Purchasing from Unreliable or Unknown Suppliers

The Problem: Some builders buy from local traders or unauthorized dealers without verifying authenticity or quality consistency.

The Consequence: Counterfeit or substandard bars may look similar to quality products but perform poorly. You have no recourse for defects, and quality inconsistency can create weak points in your structure.

How to Avoid It: Source TMT bars from established, reputable manufacturers and authorized distributors. Indostar maintains a nationwide distribution network and provides transparent traceability for every batch. Verify your supplier’s credentials, manufacturing facility, and customer testimonials before committing to large orders.

Mistake 6: Ignoring Technical Support and Guidance

The Problem: Many builders select TMT bars based on product catalogs without consulting technical experts about proper specifications for their specific project needs.

The Consequence: Wrong bar sizes, grades, or specifications lead to structural inadequacies or wastage of materials and budget.

How to Avoid It: Partner with suppliers who offer comprehensive technical support. The best TMT bars Supplier in India will help you determine the right specifications based on your project’s structural requirements, load calculations, and environmental conditions. Indostar’s technical team is available to guide you through this process.

Mistake 7: Neglecting Long-Term Cost of Ownership

The Problem: Builders focus only on initial purchase costs and overlook maintenance, replacement, and repair expenses over the structure’s lifespan.

The Consequence: Cheap bars that deteriorate quickly result in higher total costs over 20-50 years of building use.

How to Avoid It: Calculate the total cost of ownership, including durability, maintenance requirements, and longevity. Quality TMT bars from Indostar may cost more upfront but deliver superior value over decades, reducing lifetime ownership costs.

Mistake 8: Not Verifying Manufacturing Standards and In-House Testing

The Problem: Some manufacturers claim quality but don’t have robust in-house testing facilities or quality control measures.

The Consequence: Without rigorous testing, defective bars slip through and compromise structural integrity.

How to Avoid It: Choose manufacturers like SPNG Indostar that maintain fully equipped in-house laboratories and conduct multi-level testing on every batch. This ensures consistency, reliability, and adherence to the highest quality standards.

Conclusion

Selecting TMT bars is a decision that ripples through every year of your structure’s life. By avoiding these eight common mistakes and prioritizing quality over price, ensuring BIS certification, considering seismic requirements, assessing corrosion resistance, choosing reliable suppliers, seeking technical guidance, calculating total cost of ownership, and verifying manufacturing standards and make decisions that protect your investment, ensure safety, and guarantee durability.